- INDEX 2024

4 - 6 June

Dubai World Trade Center, Hall 7, Stand No: 7E291we invite you to witness a renaissance of craftsmanship at the Dubai Index Exhibition 2024. Discover our exquisite facade components and bespoke home & bathroom furniture that tell a story in every grain.

- Home Objects

- Bathroom Objects

The Role of Technology in Producing Custom and Unique Stone

The advancement of technology has transformed many industries, and the stone fabrication sector is no exception. Once primarily reliant on traditional craftsmanship, today’s stone industry leverages cutting-edge techniques that allow for precise, customizable, and highly intricate designs. This transition from manual processes to digital manufacturing has significantly enhanced the efficiency, accuracy, and creativity of stone production. In this article, we will explore the various technologies used in modern stone fabrication, particularly focusing on how these tools shape custom and unique stone products. This is you and this Role of Technology in Producing Stone.

Stone industry innovations are transforming how natural stone is used in design and construction. Advanced cutting techniques, sustainable quarrying, and new surface finishes expand possibilities for stone applications in modern architecture. These innovations enhance stone’s versatility, enabling intricate designs and eco-friendly solutions without compromising strength or beauty. The evolving stone industry continues to push boundaries, shaping the future of durable and elegant spaces.

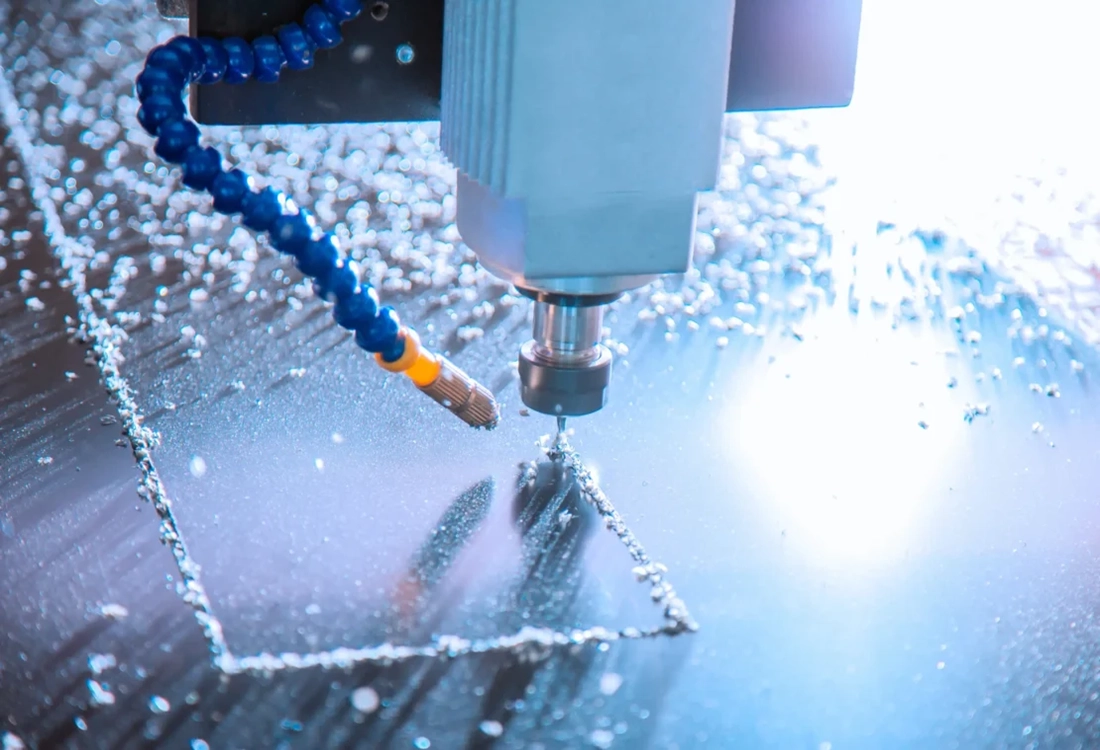

CNC Machines: Precision and Complexity

Computer Numerical Control (CNC) machines are among the most impactful innovations in the stone industry. CNC machines use computer systems to control machine tools such as grinders, routers, and mills. This technology enables artisans to carve stone with unparalleled precision. With the use of 3D modeling software, intricate designs can be rendered digitally before being physically created. CNC machines allow for the shaping of stone into complex forms that would be nearly impossible to achieve manually. These machines have one of the most important technological roles in stone production.

For instance, CNC can produce ornate engravings, curved countertops, or detailed facade components with extreme accuracy. In addition to their precision, CNC machines enhance efficiency. Designs that would have taken days or weeks to carve by hand can be completed in hours. This not only reduces the time and cost of custom stonework but also minimizes material waste by ensuring cuts are precise.

Waterjet Cutting: Versatility in Material and Design

Waterjet cutting is another technological marvel used in the stone industry. This process involves using a high-pressure stream of water, often combined with an abrasive substance, to cut through stone with minimal heat and friction. Waterjet cutters are prized for their ability to handle a wide variety of materials, including marble, granite, limestone, and even softer stones like travertine.

What makes waterjet cutting particularly valuable in the context of custom stone design is its versatility. Unlike traditional saws, waterjets can produce intricate patterns, detailed inlays, and even complex curves without damaging the material. This process is ideal for creating mosaics, patterned floors, or bespoke elements for interiors and exteriors. Moreover, because waterjet cutting doesn’t generate heat, the risk of altering the stone’s natural color or causing micro-cracks is minimized, preserving the material’s structural integrity.

Laser Scanning and Digital Modeling: Precision in Design

Before any stone is cut or carved, it must be designed, and modern technology has significantly advanced how these designs are created and replicated. Laser scanning is a technology that enables the precise measurement of existing stone surfaces or structures. This data can then be used to create a highly accurate 3D model. Laser scanning is particularly useful for restoration projects where the exact dimensions and contours of historical stonework must be replicated with precision.

In combination with digital modeling software, architects and designers can create virtual prototypes of stone products. These prototypes can be easily adjusted and fine-tuned before the actual stone is cut, ensuring that the final product meets the exact specifications of the client. This process not only saves time but also reduces the cost of errors and material waste.

Robotics in Stone Fabrication: Efficiency and Scale

Another significant advancement in stone fabrication is the use of robotics. Robots, equipped with various tools such as saws, drills, and grinders, can automate many of the processes traditionally carried out by human craftsmen. Robotic arms, guided by precise digital instructions, can cut, shape, and polish stone with incredible speed and accuracy.

Robotics is particularly advantageous for large-scale projects where uniformity is required across numerous stone pieces, such as in cladding for buildings or large flooring installations. The use of robotics reduces the time required for these tasks while ensuring that each piece meets the same standards of quality.

While robotic systems cannot entirely replace human craftsmanship, they are invaluable for repetitive or large-scale tasks that would otherwise be labor-intensive. Additionally, they can assist in tasks that require extreme precision, where even a minor deviation from the intended design would be unacceptable.

In the pictures below, you can see that modeling and designing a sculpture or a figure is done using a Chekoone robot.

Refer to this article for a better understanding and more detailed information about the operation of these robots, especially the Utopia factory robots. The role of technology in stone production has become a new stage with robots.

The Future of Stone Crafting: Exploring Utopia Stone’s Advanced 7-Axis Robots

Automated Polishing and Finishing

Polishing and finishing are critical stages in stone fabrication that have also benefitted from automation. In the past, polishing was a labor-intensive process that relied heavily on the artisan’s skill. Today, automated polishing machines can produce consistent, high-quality finishes on a wide range of stone surfaces, from countertops to wall panels. These machines use various abrasives to achieve the desired finish, whether it be a matte, honed, or polished look.

Automation in polishing has several benefits. First, it ensures a consistent quality of finish across all pieces, which can be difficult to achieve by hand. Second, it significantly reduces the time required to polish large surfaces, making it a more cost-effective option for both manufacturers and clients.

Digital Templates and CNC Routers for Custom Edging

One of the hallmarks of luxury stone design is custom edging on countertops, tabletops, and other stone surfaces. While traditional methods relied on hand tools and extensive labor, CNC routers combined with digital templates now make it possible to produce complex edge profiles quickly and with perfect consistency.

.Edge profiles such as beveled, bullnose, ogee, and others can be easily programmed into CNC machines. The use of digital templates ensures that each edge is cut to the exact dimensions specified in the design, providing a level of uniformity that is difficult to achieve manually. This not only increases the speed of production but also ensures a higher level of customization, allowing for truly bespoke stone pieces.

In the picture below, you can see an example of designing and making very precise curved edges using a CNC machine. This is one of the countertops produced by the Utopia factory.

The Impact of Technology on Custom Stonework at Utopia Stone

At Utopia Stone, the integration of cutting-edge technologies such as CNC machines, waterjet cutting, and laser scanning plays a pivotal role in producing custom and unique stone products. These advancements allow the company to create bespoke designs tailored to individual client needs while maintaining the highest standards of precision and quality. The use of technology does not eliminate craftsmanship but enhances it, enabling artisans to focus on the finer details of the design process. Utopia’s commitment to incorporating these tools ensures that its clients receive not only aesthetically stunning products but also durable and sustainable ones.

By using these technologies, Utopia Stone can push the boundaries of what is possible in stone fabrication, offering a range of products that cater to both modern and classical design preferences. Whether it’s a custom facade component, a uniquely shaped washbasin, or intricate inlays for flooring, the company leverages the best of both traditional craftsmanship and modern innovation to deliver products of exceptional quality.

Conclusion

The integration of technology into the stone industry has revolutionized how custom and unique stone products are designed and fabricated. CNC machines, waterjet cutting, laser scanning, robotics, and automated polishing have all contributed to enhancing precision, reducing production time, and allowing for greater creativity in stone design. Companies like Utopia Stone are at the forefront of this transformation, utilizing these tools to create bespoke products that meet the highest standards of craftsmanship and innovation.